OXIC – THE PROCESS

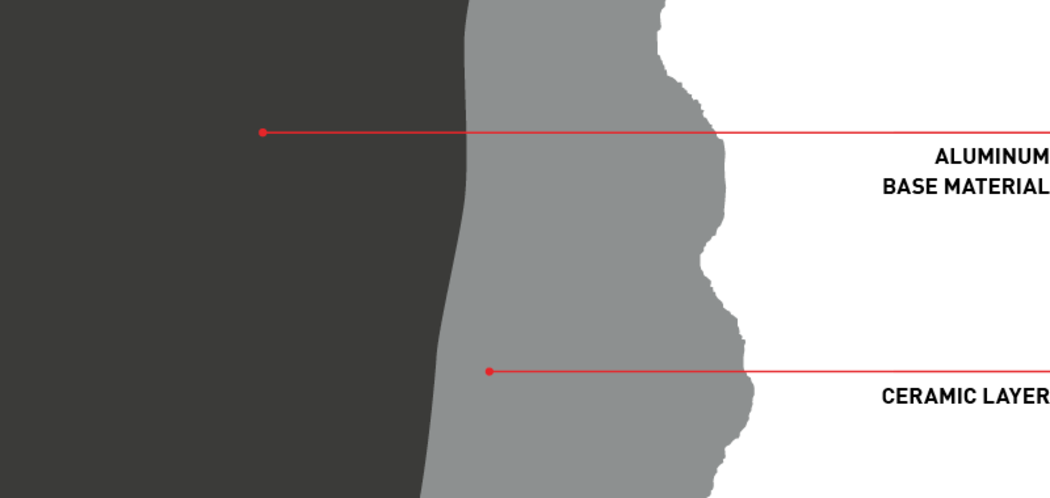

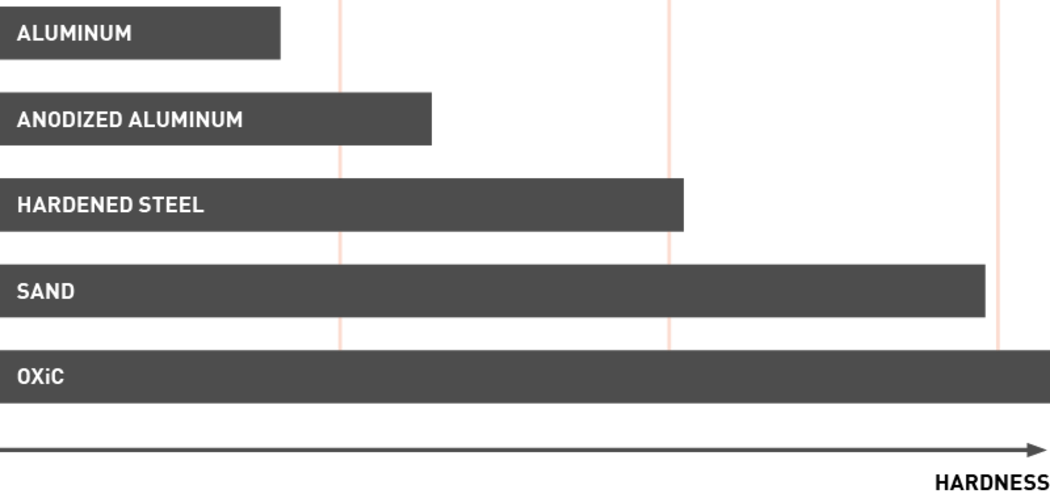

The ceramic layer is achieved similarly to anodizing, by submerging the rim in an electrolyte solution while applying an electrical tension between the rim as one electrode and the container as the other. The decisive difference between anodizing and OXiC lies in the millions of plasma discharges that occur between the electrolyte and the rim, applying high temperature and pressure on the developing oxide layer. Due to that, the developing oxide layer melts, flows and solidifies again. During this process the amorphous (not aligned) structure of the oxide converts to a crystalline (aligned) one. This is why OXiC is so hard and wear resistant.